High Temperature Industrial P84+PTFE mesh needle punched felt nonwoven filter cloth For Dust Collector:

Description:

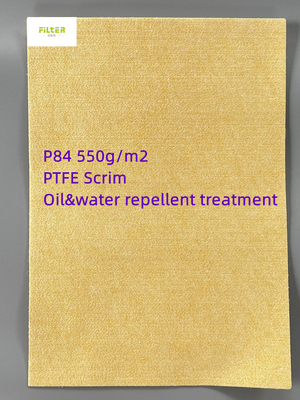

|

model

|

P84-Ptfe

|

|

color

|

yellow

|

|

characteristic

|

P84+ptfe mixed material has the characteristics of good filtration performance, good temperature and corrosion resistance, and low

flue gas emission. It is an ideal material for highly corrosive flue gas dust removal bags.

|

| Fibre |

P84 |

| Scrim |

PTFE |

| Weight(G/M2) |

450~550 |

| Thickness (mm) |

2.2 |

| Width (mm) |

≤ 2.2 |

| Length |

50m/roll |

| Finish treatment |

Singeing,Calendering,PPS dipping treatment,with PTFE membrane or oil&water repellent treatment.. |

| Air permeability (m3/m2/min): |

6~10 |

| Tensile strength (N/5× 20cm) |

Warp:>700 Weft:>1200 |

| Tensile elongation (%): |

Warp:<35 Weft:<35 |

| Temperature (ºC): |

Continue: 260 Instant: 280 |

| Anti-acid |

Excellent |

| Anti-alkali |

Excellent |

| Anti-abrasion |

Excellent |

| Hydrolytic stability |

Excellent

|

Production Features:

1. Excellent steady under high temperature and resistance to acid;

2. P84 can operate continuously,under practical and low acid working conditions at temperature up to 500°F(260°C)

3. High Filtration efficiency,high tensile strength.

4. The complex cross sectional shapes create 30~90% more collection surface area when compared to round or oval shaped fibers.

5. Low back washing pressure,maximum flexibility.

6. The unique tri-lobal fiber structure of P84 provides customers with high effciency filtration,low pressure drop,and reduced cleaning energy.

7. Excellent dust cake release.

8. P84 has irregular,tri-lonal fibers that provide better collection efficiencies and enhanced dust cake release properties.

Making method:

Our bags are sewn with 3 - needle chain stitch to ensure seam integrity. Top constructions consist of snap band, flange top, ring top, soft cuffs or raw edge. Bottom removal bags are constructed with a raw top or soft cuff. Top and bottom removal bag bottoms have disc bottoms that are sewn using an overlock (surge) stitch or lock stitch. A wear strip or custom skirts is attached to the bottom portion of the bag to prevent premature wear from bag-to-bag and bag-to-cage abrasion.

Producing Process:

Install Diagram:

Applications:

1. Asphalt mixing plant.

2. Biomass power stations.

3. Chemical and pharmaceutical industry.

4. High temperature dedusting.

5. Coal-fired power stations.

6. Food industry.

7.Non-ferrous metal and steel production.

8.Cement,gypsum and lime industry.

9.Thermal waste treatment.

More Production:

Packaging & Delivery:

Foreign Trade Team:

Exhibization:

Customer Visit:

Certificate:

Shipping Details:

|

SHIPPING

(Normally arrive port time in working days)

|

| Destination |

Express/Courier |

SHIP BY SEA |

SHIP BY AIR |

SHIP BY EMS |

| DHL/FEDEX/UPS/TNT |

| North America |

3~7 days |

15~24 days |

5~7 days |

10~12 days |

| South America |

3~7 days |

15~25 days |

5~7 days |

10~12 days |

| European Countries |

3~7 days |

20~30 days |

5~7 days |

10~12 days |

| Africa Countries |

3~7 days |

40~50 days |

5~7 days |

10~12 days |

| The Middle East |

3~7 days |

15~25 days |

5~7 days |

10~12 days |

| Australia |

3~7 days |

10~15 days |

5~7 days |

10~12 days |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!